A polymer is a substance with a structure formed of many identical small organic molecules bonded together.

A polymer is a substance with a structure formed of many identical small organic molecules bonded together.

A plastic is a synthetic material made from a wide range of organic polymers.

A bioplastic is a plastic made using renewable biomass.

A mixed bioplastic is a plastic derived from both renewable biomass and fossil fuels.

Bioplastics are manufactured using biopolymers which offer a renewable and sustainable alternative to oil-based plastics (petroplastics). Other advantages of bioplastics include novel functional properties and relatively low greenhouse gas (GHG) emissions during manufacture (see table).

Bioplastics can be produced from plant starch, cellulose, lignin (wood), oils and proteins.

Like petroplastics, bioplastics are compounds constructed of linked molecules that form long polymer chains (biopolymers).

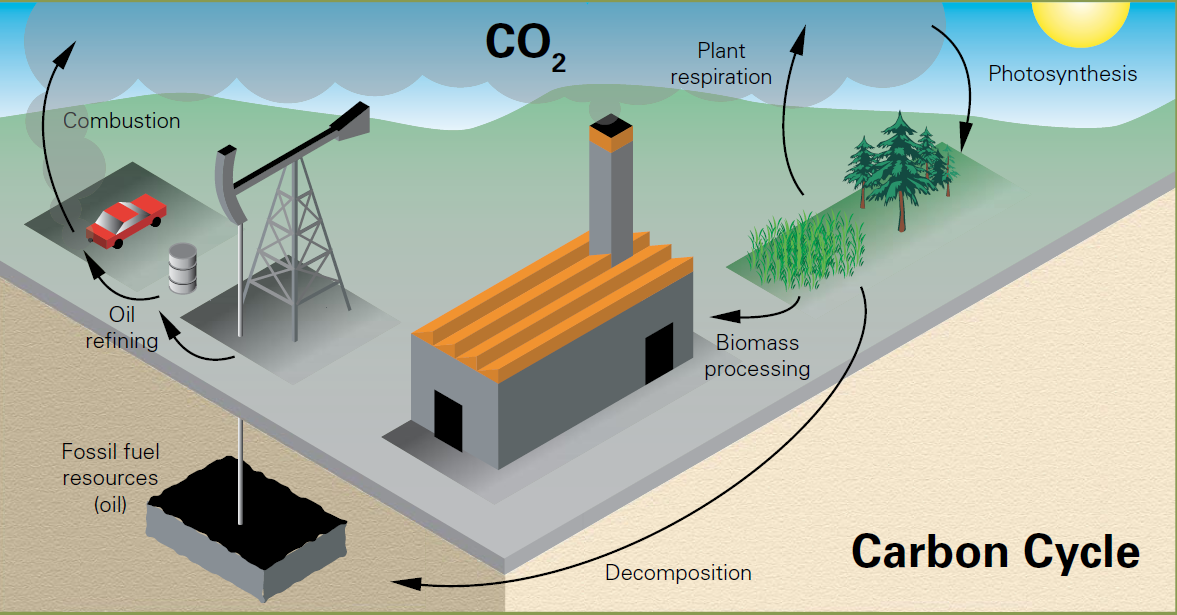

Most, but not all, bioplastics can be broken down in the environment by micro-organisms (as part of the ‘carbon cycle’ – see below) in a process called ‘biodegradation’. This process produces carbon dioxide (CO2) and water (H2O) under aerobic conditions or methane (CH4) under anaerobic conditions (in the absence of air) such as in landfill.

Mixed bioplastics are usually biodegradable, but some are not and can be either recycled or processed for energy recovery.

Note that items labeled as ‘biodegradable’ should not be confused with those marked as ‘degradable’. The latter materials break down in the environment by chemical rather than biological means.

Click here to download the complete document: Bioplastics